Closing the Loop

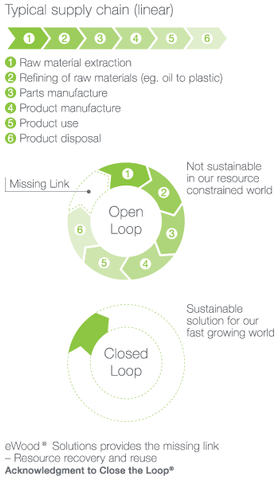

eWood Solutions’™ core focus of ‘closing the plastics loop’ is all about minimising the environmental footprint of:

eWood Solutions’™ core focus of ‘closing the plastics loop’ is all about minimising the environmental footprint of:

- government

- industry and

- individuals

through processing waste, that would otherwise end up in landfill.

eWood Solutions™ takes this waste and turns it into a functional and sustainable material (eWood®) which is:

- 100% Australian

- 95% recycled and

- 100% recyclable.

eWood® can be used to replace:

- timber

- concrete

- steel

- brick

- fibre glass

- and other virgin plastics in many applications.

eWood Solutions™ recycles a range of mixed and contaminated plastics from a spectrum of waste including, but not limited to:

- computers

- ink cartridges

- televisions

- and car parts.

Unlike any other comparable product in Australia, eWood Solutions’™ patented process allows for this wide range of plastics to be used together – making it the perfect recipe for reducing carbon output.

Its benefits aren’t just environmental. eWood® is resistant to:

- rot

- insect & termite damage

- UV and moisture

It therefore has a long-life with low maintenance.

It can be made to any dimension and assembles with ease.

eWood® is an undeniable investment for your hip-pocket and the future of the environment.

Why wouldn’t you choose eWood®?

Applications

eWood® can be used for a wide range of applications. It can replace timber, concrete, steel, brick, fibre glass and virgin plastics, and with the ability to create any dimension, the possibilities are endless.

Listed below are just some of the products that have been created using eWood®:

-

Landscaping

-

Garden edging

-

Plant boxes

-

Fencing

-

Outdoor furniture

-

Signage and posts